- Peek material seal manufacturer how to#

- Peek material seal manufacturer full#

- Peek material seal manufacturer professional#

Comprehensive quotes usually take about a day.

Request for Design & Technical Assistance – We share your urgency.

Peek material seal manufacturer how to#

Talk to a Specialist – Our specialists are familiar with your equipment and know how to improve performance and reliability.Contact Us – Talk to an engineer right now, or request a quote for the next day.General Industries – A fully engineered and customized approach to any application.Pulp & Paper – New seal technology that reduces downtime and increases reliability and productivity.Valves, Pumps & Instruments – Highly engineered seals that exceed expectations.Industrial Forging and Extrusion – New technology for new and legacy presses.Wind Energy – Large diameter seals engineered to outperform standard stock parts.

Peek material seal manufacturer full#

Food and Beverage – Offering a full range of materials that meet the unique challenges of this industry.Industrial Compressors – Seals with an unexpected level of reliability and performance.Injection Molding Machines – New and improved seals designs that are redefining OEM reliability.Hydraulic Presses – New technology for new and legacy presses.Hydraulic Cylinder Manufacturing and Repair – Increasing value for repair shops and their customers.Mobile Hydraulics – System Seals’ Zero Leak Technology in mobile mining and other harsh environments.Oil, Gas & Petroleum – System Seals helps the oil and gas industry find new levels of productivity every day.Mining – Advancing safety and reliability in mines worldwide.Steel Mills & Metal Processing – Custom designed HAGC seal systems and more for greater productivity and reliability.

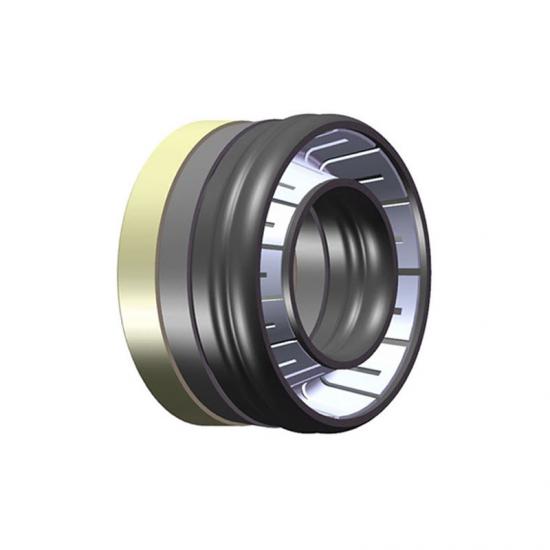

Please send inquiry to us for your high temperature application. Ģ) Casting, forging and heat treatment equipment in the machinery manufacturing industry ģ) Ceramic, glass, enamel, brick and tile equipment Ĥ) Thermal power plants and boilers on ships, etc. PEEK seal types: PEEK back-up rings,spring energized PEEK jacket seals, PEEK oil seals,etc.ġ) Metallurgical industry equipment, such as coking, ironmaking, steelmaking, steel rolling, etc. Peek material: Pure PEEK, carbon fiber filled PEEK,PTFE filled PEEK,Glass fiber filled PEEK

Peek material seal manufacturer professional#

With these excellent comprehensive properties, PEEK materials have a wide range of applications in aerospace, machinery, petroleum, chemical, nuclear power, rail transit and other fields.īOSS Sealing Solutions is a professional PEEK seal expert on designing and manufacturing different PEEK seals to meet various requirement of client. PEEK material has excellent resistance to sliding wear and fretting wear loss, especially it can maintain high wear resistance and low friction factor at 250 ℃ in addition, PEEK material is easy to extrude and injection molding. PEEK material has good chemical stability, strong corrosion resistance to acids, alkalis and almost all organic solvents, and has flame retardant and radiation resistance properties It has high rigidity, dimensional stability, and low linear expansion coefficient, which is close to metal aluminum materials PEEK material has outstanding high temperature and heat resistance, which can be used for a long time at 260℃, and the instantaneous use temperature can reach 300℃ It can replace traditional materials such as metals and ceramics in many special fields, and has made outstanding contributions to reducing quality and improving performance. PEEK material is a semi-crystalline aromatic plastic engineering plastic with excellent physical and mechanical properties.

0 kommentar(er)

0 kommentar(er)